coal crusher efficacité

Vibration Test and Shock Absorption of Coal Crusher

Coal crushers are important auxiliary dynamic machines in thermal power plants and are used for crushing and processing raw coal. However, a

More

Energy Efficiency Optimization of Coal Conveying Systems

Coal conveying systems mainly includes belt conveyors and crushers. On the basis of conveyor and crusher energy models, this paper presents an energy efficiency optimization strategy for coal conveying systems by taking feed rate, belt speed and

More

Coal Crushers Coal Pulverizers Mills Williams Crusher

How Do You Pulverize Coal? Coal is crushed to desired fineness between spheres or cylindrical rollers. After that, air from the boiler is heated to around 330°C (650°F). The raw coal is then fed into the pulverizer where

More

Coal Crusher, Coal Crushing Machine, Coal Crusher

Coal Crusher. Since the compression strength of coal is about 5-50, general crusher is able to deal like jaw crusher, impact crusher and roll crusher, etc. However, there exist special requirements for processing and using

More

Coal Crushers, 1.6mm / 4.75mm Final Particle Size

Holmes Hammermill Coal Crushers reduce bulk samples of coal and coke with rotary-swing hammers. The enclosed cases, covered feed hoppers, and rugged cast iron housings ensure safe and efficient operation with low

More

McLanahan Coal

Employing the basic reduction principles, McLanahan crushers reduce coal at maximum volume using compression, impact, attrition and shear forces. Crushers engineered by McLanahan consume less power and are able

More

MEKAR JAYA TECHNIC - Coal crusher

Coal Crusher (crusher batu bara) yang kami produksi kapasitas mulai dari 1 ton/jam - 20 ton/jam. Dengan sistem hammer mill, mudah dalam pengoperasian, dan perawatan serta kebutuhan power yang efesien. Banyak digunakan untuk menghancurkan batu bara

More

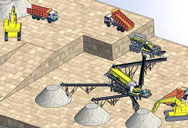

Coal Crusher Crushco

A range of Coal Crushers, built to perform in the challenging conditions of opencast coal mining. ROBUST FEATURES FOR MAXIMUM RELIABILITY We have applied 18 years of Crusher experience to design manufacture a range of robust heavy duty COAL

More

CRUSHER BATU BARA - coal crusher

Coal crusher (crusher batu bara) yang kami produksi kapasitas mulai dari 1 ton/jam - 150 ton/jam. Dengan sistem hammer mill, mudah dalam pengoperasian, dan perawatan serta kebutuhan power yang efesien. Banyak digunakan untuk menghancurkan batu bara

More

Holmes Hammermill Coal Crushers - Measur Materials Testing

Small Holmes Hammermill Coal Crusher (230V/50Hz or 230V/60Hz) Two sample collection containers – 10 and 35lb (4.5 and 16kg) capacity; Two screen plates – 3/16 1/16in (1.6 and 4.8mm) or other customer-specified sizes, or; Large Holmes Hammermill Coal Crusher (230V/50Hz or 230V/60Hz) Two screen plates in customer-specified sizes

More

How does a coal crusher work? - LinkedIn

A coal crusher is a machine that processes coal into smaller pieces. It typically consists of a series of crushers such as jaw crushers, cone crushers, impact crushers, and others. Each crusher ...

More

(PDF) UGC JOURNAL - AUTOMATION OF COAL

PDF On Mar 18, 2021, s. Premalatha published UGC JOURNAL - AUTOMATION OF COAL Find, read and cite all the research you need on ResearchGate

More

(PDF) SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

A simplified model (kinematic diagram) of the mechanism of the double buckling jaw crusher is shown in Fig. 20. The mechanism in question is a six membered mechanism formed by attaching a binary ...

More

Hard coal preparation in a single stage crushing circuit for ...

The article concerned the problem of coal preparation for gasification purposes. The main aim was to design the coal crushing circuit, which would produce the material within the particle size range between 0.5 and 5 mm. The one-stage crushing circuit based on hammer crusher was proposed.

More

Crusher Batubara - pt. Penta Inti Persada, Manufaktur Coal

Roll Crushers are simple in design and construction, long lasting, economical, and versatile. Two roll crushing surfaces operate at a fixed distance apart, so product size is much more consistent. Both oversized pieces and fines are minimized. Double roll crushers reduce primarily through compression, although some shear is obtained with toothed rolls.

More

Vibration Test and Shock Absorption of Coal Crusher Chambers

The coal crusher generates large vibrations when crushing coal blocks, which can affect the equipment itself, as well as the safety of the structure. In order to study the dynamic characteristics of coal crusher, a finite element model of the coal crusher chamber in the Shangluo power plant was built by using ABAQUS. Firstly, modal and

More

Crushing Chamber - an overview ScienceDirect Topics

Gyratory crushers are principally used in surface-crushing plants. The gyratory crusher (Figure 6.5) consists essentially of a long spindle, carrying a hard steel conical grinding element, the head, seated in an eccentric sleeve.The spindle is suspended from a “spider” and, as it rotates, normally between 85 and 150 rpm, it sweeps out a conical path within

More

Roll Crushers TAKRAF - TAKRAF GmbH

25: 2,500 mm - pitch circle roll diameter. 37: 3,700 mm - roll length. Our largest roll crushers are equipped with TAKRAF designed and developed gearboxes that are specifically applicable to heavy-duty crushing applications at up to 1,500 kW of motor power. Each gearbox is manufactured and tested at our workshop in Lauchhammer, Germany.

More

Coal crusher - American Pulverizer Company

In order to bring the mine coal to a commercially acceptable size, the coal is usually run through a coal crusher which normally reduces it to pieces no larger than 3/4 to 1 inch in size. However, some of the coal from the mine is already in the 3/4 to 1 inch size range and when this coal passes through a crusher, much of it changes to fines which is undesirable.

More

EFFECTIVENESS SEBAGAI LANGKAH PENINGKATAN EFEKTIFITAS MESIN COAL ...

Time pada mesin Coal Crusher secara keseluruhan antara lain, mesin berhenti tidak terencana pada saat produksi sedang berjalan, material tidak standar dan standar kerja operator dalam menjalankan mesin. Secara keseluruhan Lost Time mesin Coal Crusher dapat disajikan pada 1.2Tabel. Total Lost Time Coal Crusher (M eni t) 25,000 15,000

More

Coal Crushing and Conveyer System - Research Publish

crusher, Double roll crusher, pulverizers, ring granulators etc. The crushed coal is transported from crusher to thermal power plant through conveyor belt and is used in boiler. The type of conveyors used for transferring the coal are listed below(1) Belt conveyor (2) Screw conveyor (3) Bucket conveyor (4)Grab Bucket Conveyor (5) ...

More

McLanahan Coal

McLanahan specializes in a variety of crushing solutions to reduce ROM coal to a transportable and marketable top size. McLanahan crushers can take the coal producer through all stages of crushing process, from initial

More

Coal Crushers, 1.6mm / 4.75mm Final Particle Size - Gilson Co.

LC-201 model is recommended for crushing 2in (51mm) and smaller samples. It processes at a maximum rate of about 1,000lb (454kg) of coal material per hour. The final size is approximately 1/16in (1.6mm) and the rotor speed is 3,450rpm. Covered Feed Hopper capacity is 0.40ft ³ (11.3L), and the crushing chamber is 7x6in (178x152mm).

More

MEKAR JAYA TECHNIC

PT.MEKAR JAYA TECHNIC adalah perusahaan yang bergerak di bidang kontraktor dan supplai batu tahan api dan insulation (Refractory and Insulation). Didirikan pada tanggal 16 April 2002 dengan Surat Ijin Usaha Nomor : 510/47/404.62/2010 dan No TDP 13.17.3.51.01522.

More

Spring Support of Coal Crusher Foundations in Power Plants

crusher foundations. • With spring support, the crusher and its deck are usually supported on just two beams framed into the nearest building column. Only the dead load of the crusher and deck are added to the column load, as dynamic loads are eliminated by the vibration isolation sys-tem. The layout of the structure is thus greatly simplified.

More

How to operate a coal crusher machine? - LinkedIn

To operate a coal crusher machine, follow these steps: Make sure the crusher is in good working condition. Before starting the crusher, make sure it is lubricated and properly supplied with coal ...

More

Research on Structural Design of Coal Crusher House in Thermal Power

In the coal crusher house, floor beams directly support-ing the coal crusher are not subject to vertical vibration calculation when their high-span ratio meets the require-ments of Table 1[1 ...

More

Coal Crusher Facility, Construction (Technical Report) OSTI.GOV

Extensive factory and field testing of the hydraulic borehole coal mining tool was performed. The tests: (1) characterized cutting nozzle and crusher wear and reliability; (2) characterized cutting, cavity slurry flow, crushing, and slurry pumping processes under field conditions; and (3) compared laboratory cutting and pumping rates with those

More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER ...

Abstract and Figures. A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic ...

MoreArticle aléatoire

- role de scm dans raymonds

- pages super broyeur Indonésie boulets 3b cas 3b malaisie client

- micro concasseur Indonésie cône max 10t

- Beguin Extraction Du Gypse Dans Kenya

- concasseur Indonésie mâchoires bubuk

- moulin Indonésie raymond fabricant

- bomba Meulage de pierre bombas

- concasseur Indonésie percussion 10

- machine de concassage de terre complète

- achat moulin humide en ligne

- broyeur Indonésie impact pour les pigments d oxyde de fer

- peut concasseur en allemagne Indonésie vendre

- fournisseur Allemagne de l'utilisNouvelle Caldonia de concassage de pierre

- Meulage de pierre y pioneer

- quebradoras de cereal

- karnataka Afrique concasseur de pierre fden

- Calcaire taux de mobile de concassage en Nouvelle Caldonia

- composante de l''industrie minière nigeria

- diagramme synoptique de la centrale thermique

- des travailleurs de l'usine de loterie 2012 en Nouvelle Caldonia feldspath

- de concasseur Indonésie mâchoires machine ppt

- krisbow pressure cleaner steam

- effet de la taille des médias en broyeur Indonésie boulets broyage Indonésie sec

- four Indonésie four rotatif en fer

- jual concasseur Indonésie mâchoires bouchon tph

- pequenos fabricantes de molino de bolas en coimbatore

- Batteurs De L Usine De Marteau Fournisseurs

- dsulfuration la chaux dans l usine de minerai de fer

- matériel de construction Afrique concasseur de Kaolin

- prix des équipements de broyage en afrique du sud